AUTOMATION SOLUTIONS FOR THE PHARMACEUTICAL INDUSTRY

The pharmaceutical industry is driven by the need for precision, efficiency, and regulatory compliance. At PJM, we understand the complexities of pharmaceutical production and offer automation solutions that ensure seamless and efficient operations. Our solutions are designed to optimise production lines, improve product quality, and ensure compliance with global regulations such as FDA and EMA guidelines.

OUR SOLUTIONS FOR THE PHARMACEUTICAL INDUSTRY

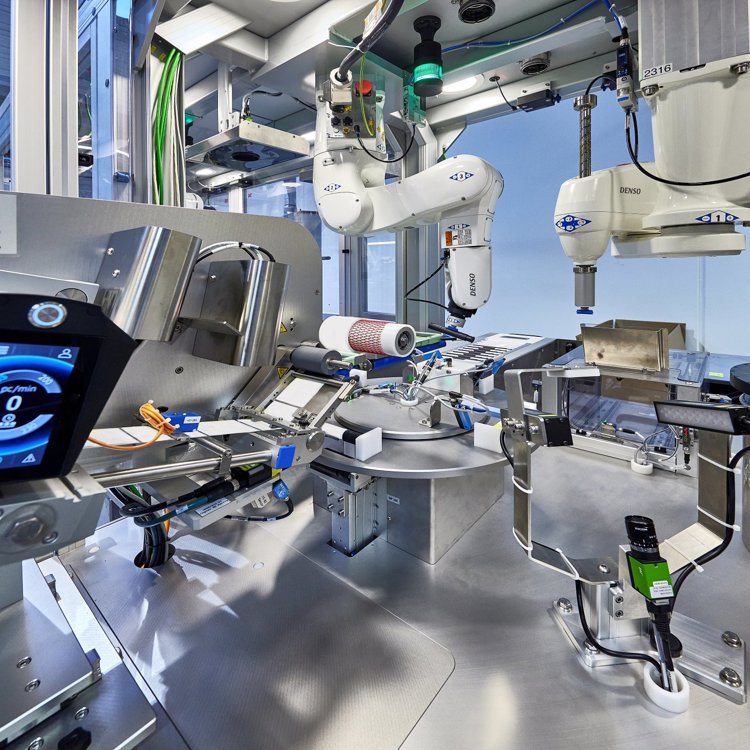

PHARMA PACKAGING EQUIPMENT

Our solutions offer advanced vision control, labelling, serialisation and integration with MES.

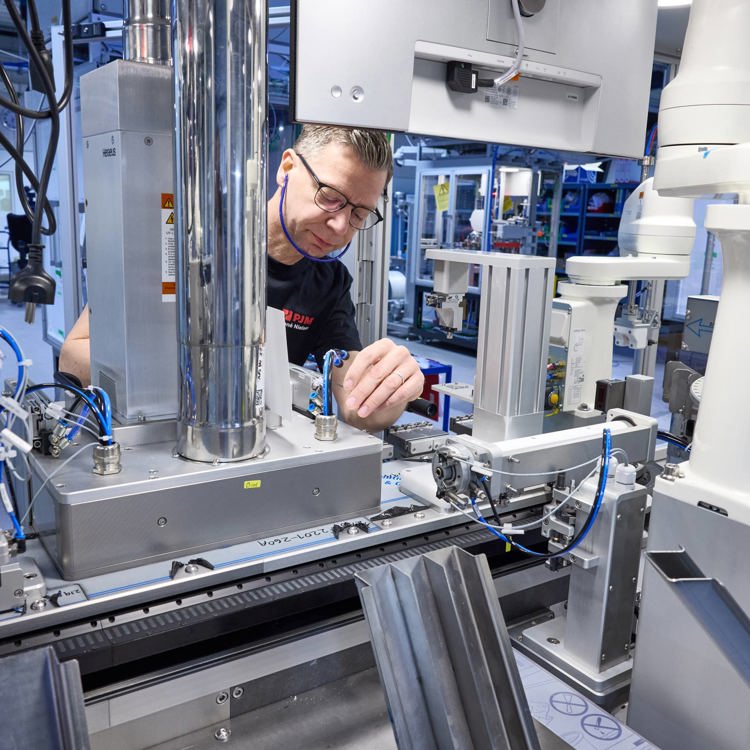

MEDICAL DEVICE ASSEMBLY

Assembly of pharmaceutical medical devices for diabetes treatment, e.g. pre-filled syringes.

MATERIAL HANDLING EQUIPMENT

Material Handling equipment for sterile production, e.g. filling- and inspection lines.

EOL PACKAGING SOLUTIONS

Solutions for box packaging of pharmaceutical products, e.g. cartons.

PJM's pharmaceutical automation services include everything from assembly lines to packaging systems, all tailored to meet the highest industry standards. By integrating state-of-the-art automation technologies with your production processes, we help pharmaceutical companies reduce human error, improve traceability, and ensure consistent product quality.

WANT TO KNOW MORE?

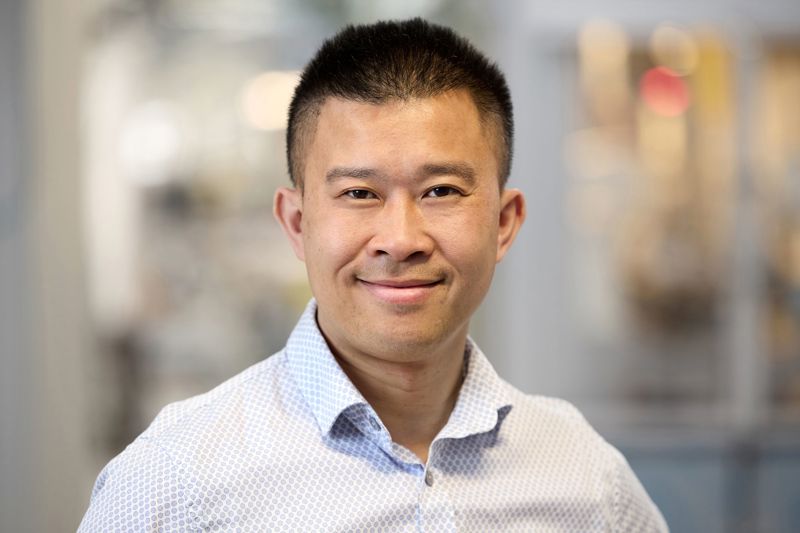

Are you curious to explore how we approach the pharmaceutical market with valuable automation solutions? Reach out to Nam Nguyen, our Key Account Manager for Pharma, below, and let’s explore how we can help you with your upcoming project.

Nam Nguyen

Key Account Manager

+45 51 43 48 55