ADVANCED AUTOMATION SOLUTIONS FOR INDUSTRIAL MANUFACTURING

The industrial manufacturing sector faces constant pressure to optimise production lines, reduce operational costs, and improve overall efficiency. At PJM, we specialise in providing automation solutions that address the complex demands of industrial manufacturing, from assembly to material handling and packaging. Our solutions are designed to streamline production, increase throughput, and improve system reliability while minimising downtime.

OUR SOLUTIONS FOR INDUSTRIAL MANUFACTURING

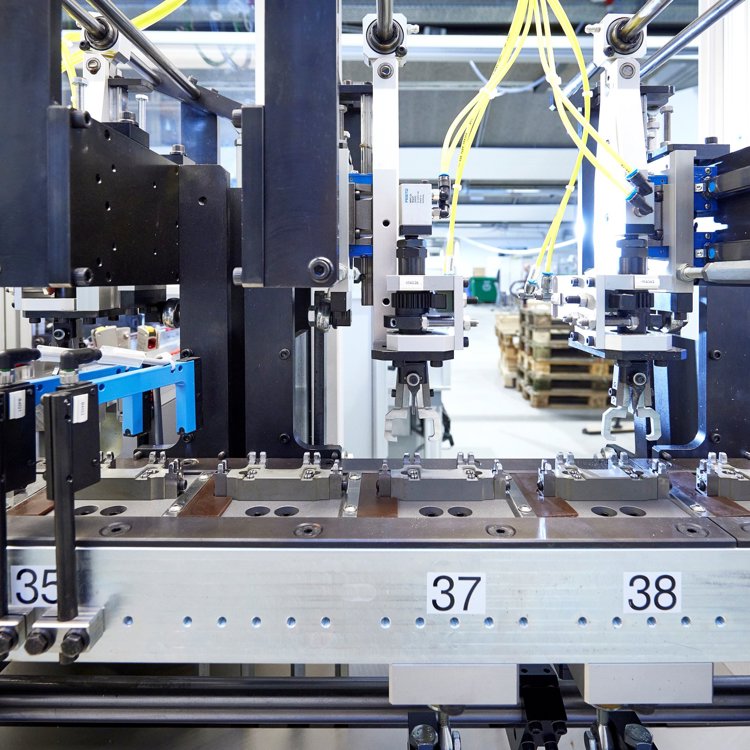

ASSEMBLY AND INSPECTION

Assembly and inspection of valves, transducers, sensors and similar products.

ASSEMBLY AND DECORATION

Assembly and decoration of products, including laser marking or pad printing.

PACKAGING SYSTEMS

Robust packaging systems that improve speed and accuracy

ADVANCED CONTROL SYSTEMS

Advanced control systems for enhanced reliability and real-time monitoring

WANT TO KNOW MORE?

Are you curious to explore how we approach the industrial manufacturing market with valuable automation solutions? Reach out to Flemming Holm, our Key Account Manager for Industrial Manufacturing, below, and let’s explore how we can help you with your upcoming project.

Flemming Holm

Key Account Manager

+45 24 80 37 46