DIGITAL TWIN PROTOTYPING

Shorter time-to-market with digital twin prototyping and virtual commissioning.

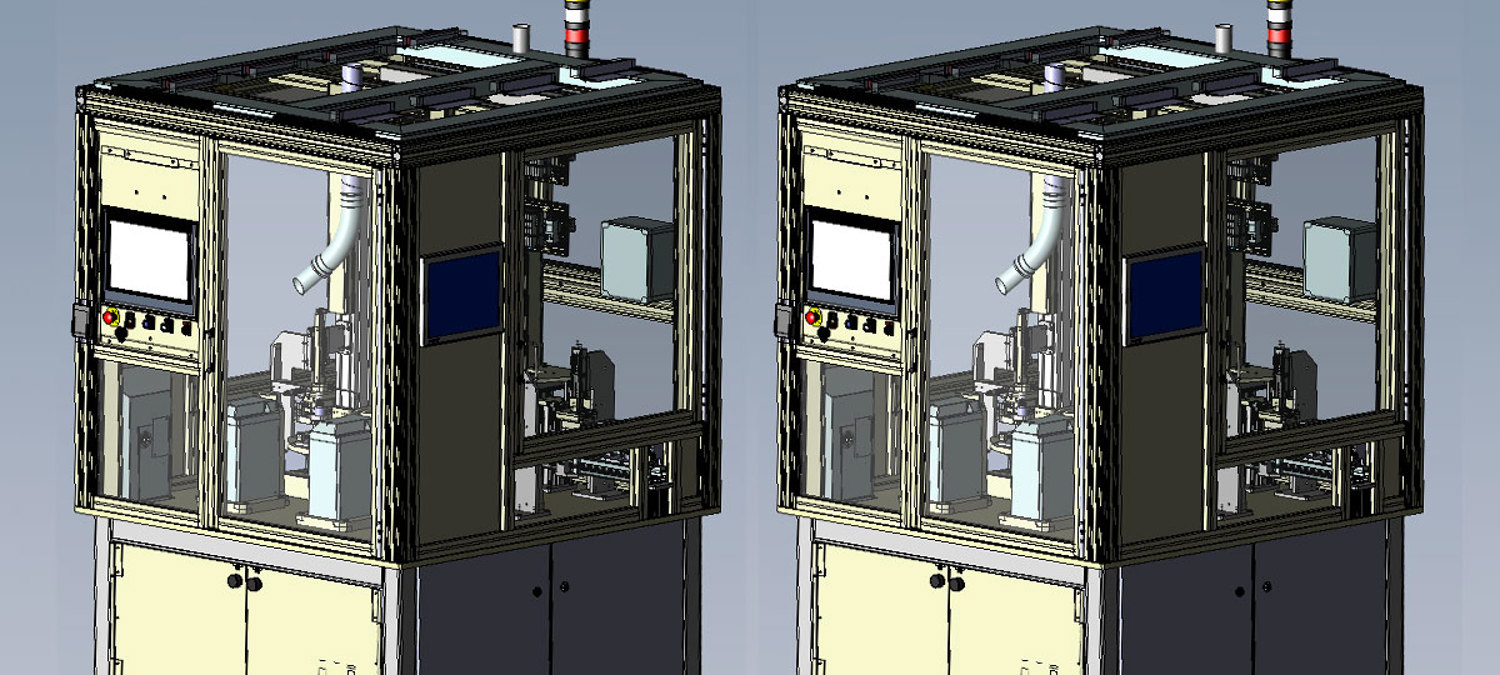

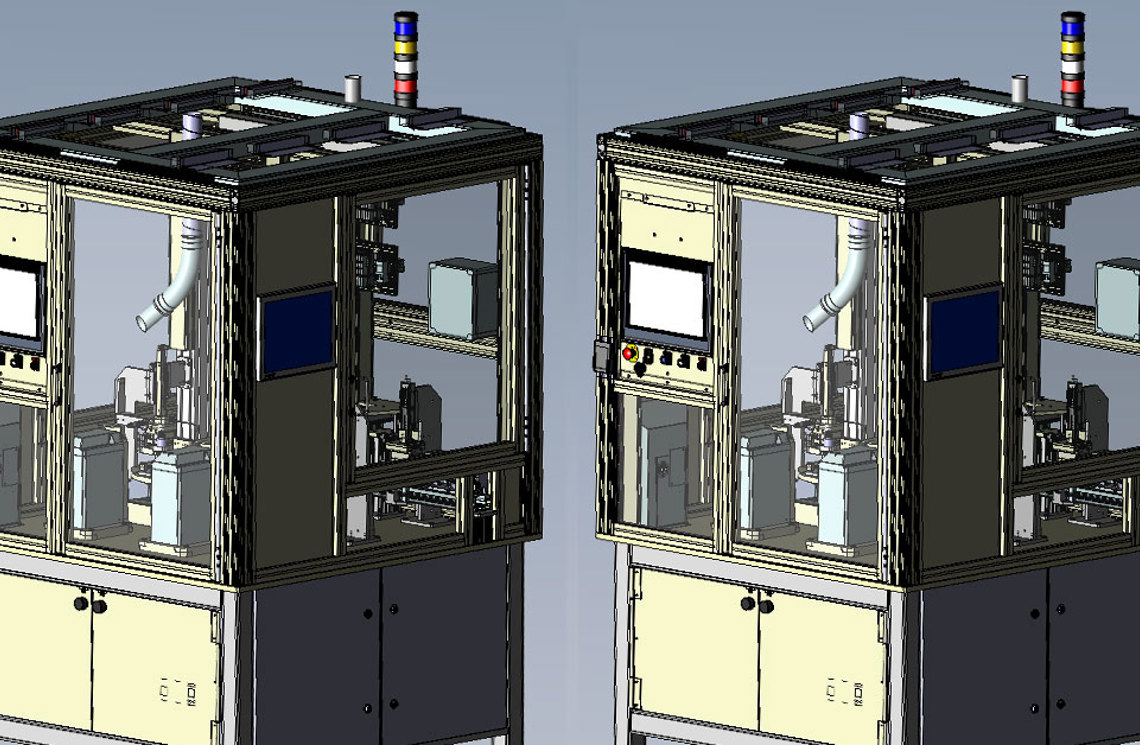

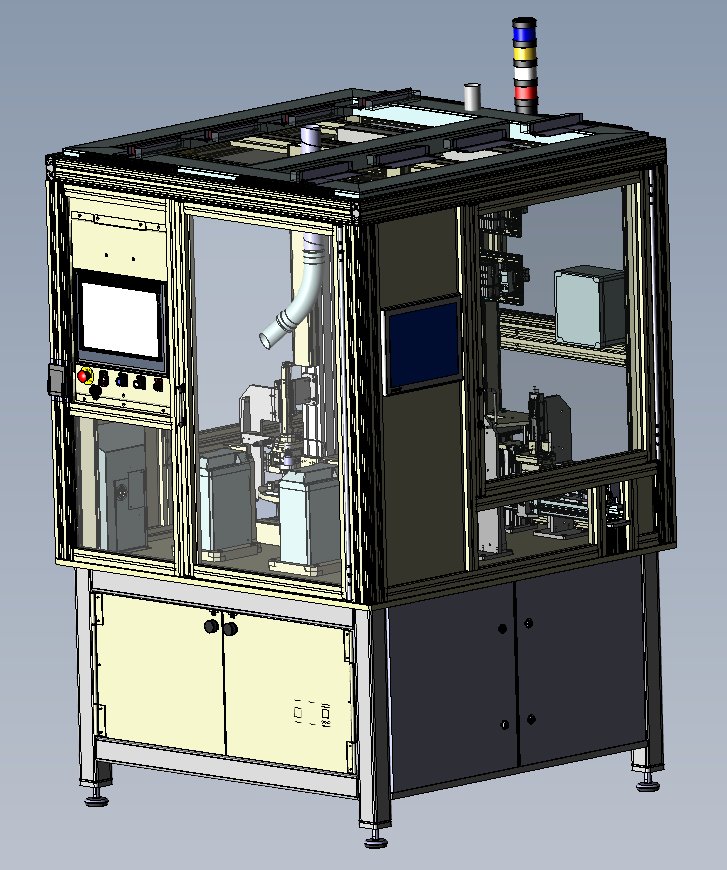

In this blog post: We are employing digital twin prototype and virtual commissioning technology to run extensive testing on new machines – long before they are built.

This video shows various functions of the machine as a virtual installation

CUTTING COMMISSIONING TIME AND TIME-TO-MARKET

Jakob Nors, innovation manager at PJM, explains:

“We are now capable of constructing a fully working digital model or selected critical parts of machines that we build. We can design and to a large extent test the software and the user interface as well, and this means that we can now model how the machine will run, long before it is built. By doing so, we can cut the in-house physical commissioning time– because we will have verified correct functionality in the digital model in advance.”

At PJM, we expect to expand this technology to become part of our front-end design processes – which means that we can offer our customers the possibility of virtual testing as a part of the development process.

ADVANTAGES:

- Thorough test of program can be run before the machine is built

- Desktop testing of user interface based on the real PLC program and simulated components

- Earlier start of commissioning phase means shorter time-to-market

- More flexibility in planning software resources throughout a project

- Better time to fix possible bugs before commissioning begins