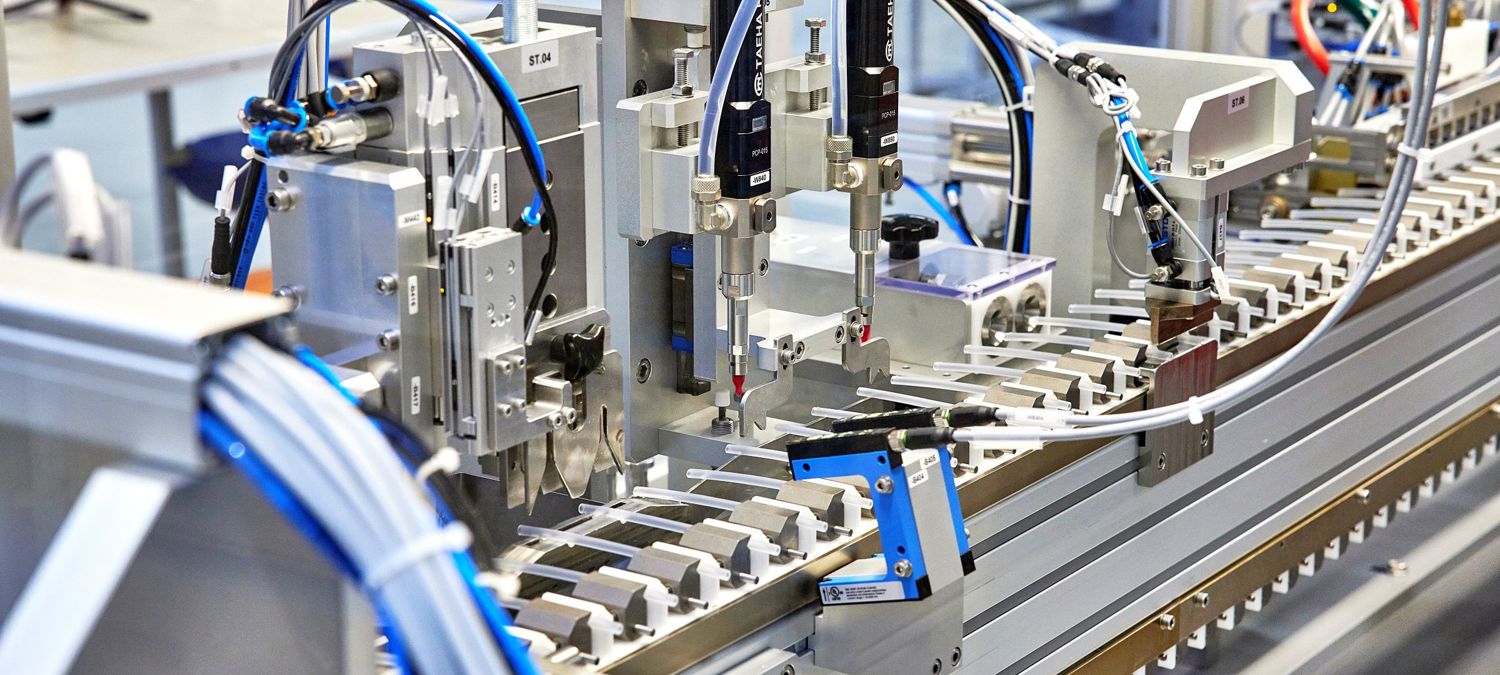

EFFECTIVE CUSTOM-MADE SOLUTIONS WITH MINIMAL PRODUCTION FOOTPRINT

For more than 30 years PJM has designed customised automation solutions for our customers in the medical device (medico) industry. During those years we have collected valuable insights into the standards you are required to meet in your production as well as how we develop automation solutions that meet your specific needs and requirements.

From idea to operation our skilled specialists use their experience and creativity to provide you with a solution that adds value to your production by delivering the highest possible output while maintaining the highest level of product quality.

RELIABLE HIGH-PERFORMING SOLUTIONS

Our automations solutions are installed all over the world – some are brand new, and others are still going strong after more than 30 years.

We understand the importance of keeping your production flow free of disruptions. Because of this we design and build solutions for your production line with durability and stability in mind.

In the production lines we develop, stability and flexibility aren’t mutually exclusive – it is quite the opposite. One of our strengths is integrating several variations into our designs without you having to compromise on performance and quality. We design and program your solution, so it is easy and safe to operate, including when you are changing between different product variants. By partnering with us you can be sure to get a strong addition to your production with a high-performance solution built to handle variations with a minimal changeover time.

MAKING IT ALL COME TOGETHER

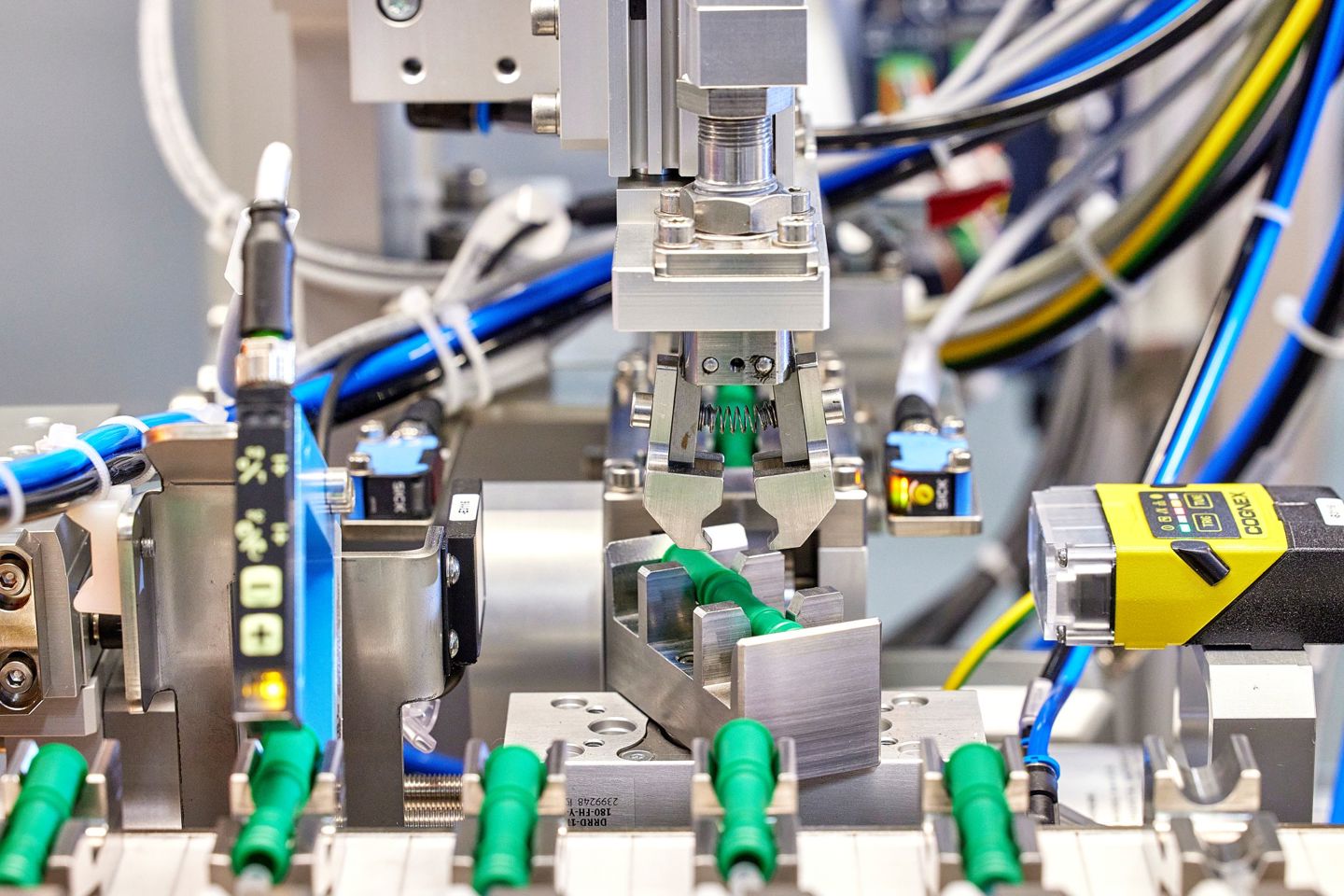

One of our fields of expertise within medico-solutions is machines that handle catheters. Niels Henrik Rohde, one of our Mechanical Engineers, has been designing catheter solutions for our customers since the beginning of the 90’s. He describes his approach to designing these complex lines:

“I have designed several machines that assemble catheters throughout the years. When I design these machines, I always have the end-user in mind. The final solution must be capable of handling all the different variants – material, length, diameter – so that our customers don’t need separate solutions for each product variant. However, the flexibility must not be at the expense of product quality – and it doesn’t have to be. My colleagues and I always take every scenario into account in our designs to ensure that the final solution produces quality items that meet the needs of the end-user. “

When designing catheter assembly lines there are many aspects that need to be taken into consideration, because of this Niels Henrik Rohde focus on having a strong dialogue with the customer throughout the design-phase to make sure that they end up with the best possible solution. He elaborates:

“Our catheter solutions are streamlined to make sure that the process or processes are completed efficiently with no unnecessary waste of production space or time. My key responsibility as lead engineer is to bring my experience and knowledge into play when working on a project. In close collaboration with the customer, others from the project team and I review the design from every angle to make sure we develop the optimal solution for the customers’ production needs. When we work together with a customer, we ensure that they get a flexible production line that maintains high performance and quality across variations while also being safe to operate. “

ADDING VALUE THROUGH STRONG PARTNERSHIPS

At PJM we strive to add value to your production set-up by taking on the role of your strategic automation partner from idea to operation – and beyond. From the very beginning your dedicated project team strives to assess and understand your needs and requirements while using their expertise to identify opportunities for improvements to enhance the overall performance of the solution. Kenneth Thielsen, Key Account Manager for our Medico customers, describes:

“We take our role as your automation consultant very seriously. In the initial stages of a project, you will work closely together with our Front-End Designers to identify critical processes or functionalities that require extra attention to ensure optimal performance. We dedicate the necessary time and resources at the beginning of the project to provide you with the strongest business case possible before handing it over to our project execution team. “

In addition to our automation solutions, we have a strong documentation and validation department that is part of the project team, so we can deliver complete documentation and validation packages that can be implemented directly into your set-up.

We can also provide you with a complete turnkey solution. As part of the BILA Group we work closely together with our sister companies to incorporate an end-of-line solution to the finished product line.

As your automation solutions partner, we integrate the required processes in a solution that takes up the smallest possible production space while delivering the highest possible output. We can also provide you with a product package that goes beyond the individual machine.

If you want to know more about our documentation and validation competencies. Click here to see more about how we strengthen validation and documentation at PJM.